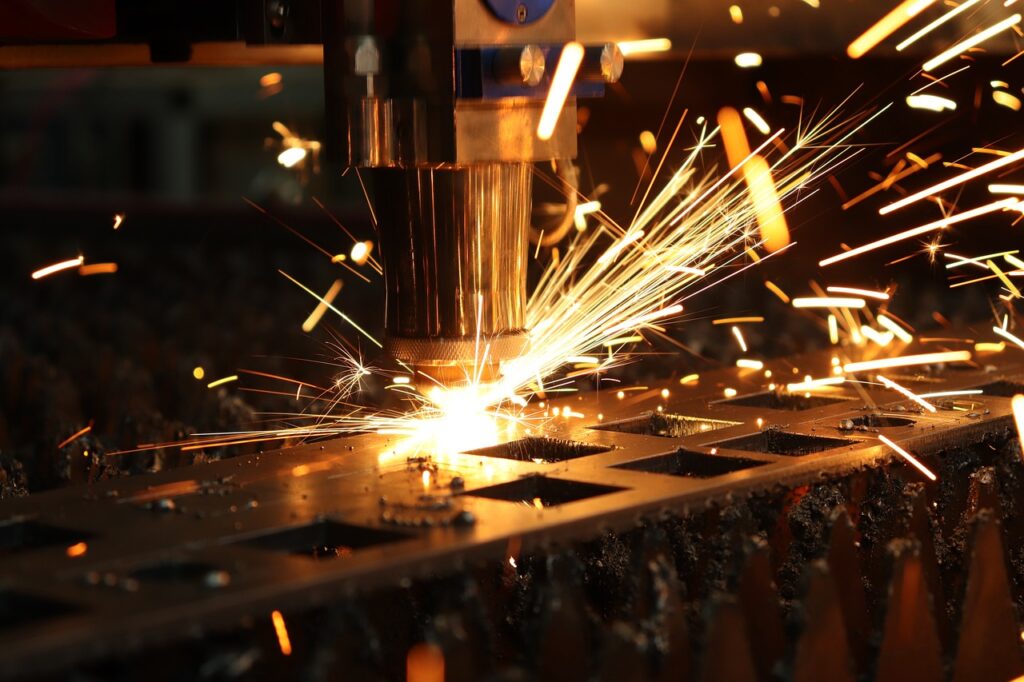

In today’s world, you cannot afford to choose between customization and efficiency. Your customers demand tailored solutions with quick turnarounds, and at Wesgar, Precision Sheet Metal Fabrication and Machining Specialists, we are committed to meeting those needs without compromises. That is why we have developed an approach that integrates automation into a high-mix, low-volume (HMLV) environment, ensuring you get both the flexibility and fast delivery times you deserve.

Why HMLV Production Is Your Advantage

You want products that match your unique specifications, delivered on schedule and without quality sacrifices. However, HMLV manufacturing can feel like running a race on a constantly changing track. Complex orders, frequent changeovers, and short lead times can strain even the most advanced factories.

The good news? We have found a way to handle this complexity at scale, so you do not have to worry about unpredictable lead times or inconsistent quality.

Our Tailored Approach: Automation that Adapts to Your Needs

We have designed our automation strategy around what matters most to you: consistent quality, shorter lead times, and the agility to handle any customization you throw at us. Here is how:

- Modular Automation Systems

Think of our flexible production cells as a custom-fit toolkit, ready to tackle any job:

- Rapid Reconfigurations: Switching from one custom order to another without long delays.

- Robotic Welding Cells & Programmable CNC Machines: Precisely adapt to different part shapes, materials, and designs—ensuring accuracy and reliability every time.

What’s in it for you? Faster order fulfillment and the confidence that each product meets your exact standards. We have you covered, and unlike other companies who are set to run higher volume, uninterrupted production lines, Wesgar has made this flexibility and part of our daily processes.

- ERP-Driven Scheduling Systems

Our advanced scheduling software works like a skilled conductor, making sure every resource and machine is in perfect sync.

- Real-Time Adaptability: Quickly adjust production priorities to meet changing demands.

- Optimized Delivery Times: We align production schedules with your timelines to keep your projects on track.

What is the bottom line for you? Predictable lead times, transparent timelines, and peace of mind.

- Collaborative Robotics (Cobots)

Our Cobots are engineered to work alongside humans, handling repetitive tasks with precision:

- Enhanced Quality Control: Automated consistency reduces defects and rework.

- Efficiency and Safety: Skilled technicians focus on customization and value-added work, while Cobots handle repetitive, time-consuming tasks safely.

Result for you? More consistent quality and quicker response to unique requests—all with improved reliability.

The Benefits: Efficiency Without Trade-Offs

Our integrated automation solutions bring tangible advantages to your bottom line:

- Shorter Lead Times: Complex, custom orders are fulfilled faster than traditional methods.

- Consistent Quality: Every product meets the same exacting standards—no matter how varied your order list.

- Scalability with Precision: Our advanced manufacturing processes and flexible production capacity ensure that as your business grows, we can scale seamlessly with you. Whether you’re ramping up for a large project or need to accommodate fluctuating demand, you can rely on us to deliver precision and consistency without compromise.

Real Success in Action

When one of our clients requested a series of custom panels with unique specifications, we used our modular robotic welding cells and ERP-driven scheduling to:

- Deliver 20% Faster than standard methods.

- Achieve Zero Defects on a complex, highly customized run.

- Exceed Expectations with on-time delivery and flawless quality, proving that flexibility does not have to slow you down.

- Drive Repeat Business with End-User Satisfaction: Our commitment to quality, with speed and precision, not only met the client’s specifications but also delighted their end-users, leading to repeat orders. This success story highlights how our solutions help you strengthen relationships with your customers and grow your business.

Your Roadmap to Success

By adopting a similar strategy, you can:

- Reduce Downtime & Lead Times: Keep customers happy with faster deliveries.

- Maintain Consistency in Quality: Retain their trust with every repeat order.

- Control Costs & Improve Margins: Offer competitive pricing without sacrificing quality.

Join Us in Building Your Competitive Edge

At Wesgar, we are not just talking theory; we are practicing it daily so you can stay ahead. If you are struggling with the challenges of HMLV production, we’re here to guide you through a proven roadmap to greater efficiency and flexibility.

Wesgar has grown over the last 6 decades to become one of the largest Customer Sheet Metal Fabricators in the Pacific Northwest, and this is a result of the great Consultative Business Partnerships we have with our Amazing Customers. We continually work with our customers, and support them in growing their business, and in turn, allowing Wesgar to flourish, and have the long-term strategic alignment in place to be a key Partner for the next 60 years.

- Contact Us: Let’s discuss how our tailored automation solutions can elevate your operations.

- Stay Informed: Subscribe to our newsletter for industry trends and innovations insights.

- Share Your Thoughts: We’re all ears—leave a comment below and let us start a conversation.

Ready to elevate your manufacturing capabilities?

Reach out today and discover how we can help transform your HMLV challenges into growth opportunities. Let us shape a more efficient, agile future for your business together.