The Wesgar Advantage: A True Partnership

Wesgar isn’t your typical supplier. As partners, we consider ourselves honorary members of your team and just as vested in your success.

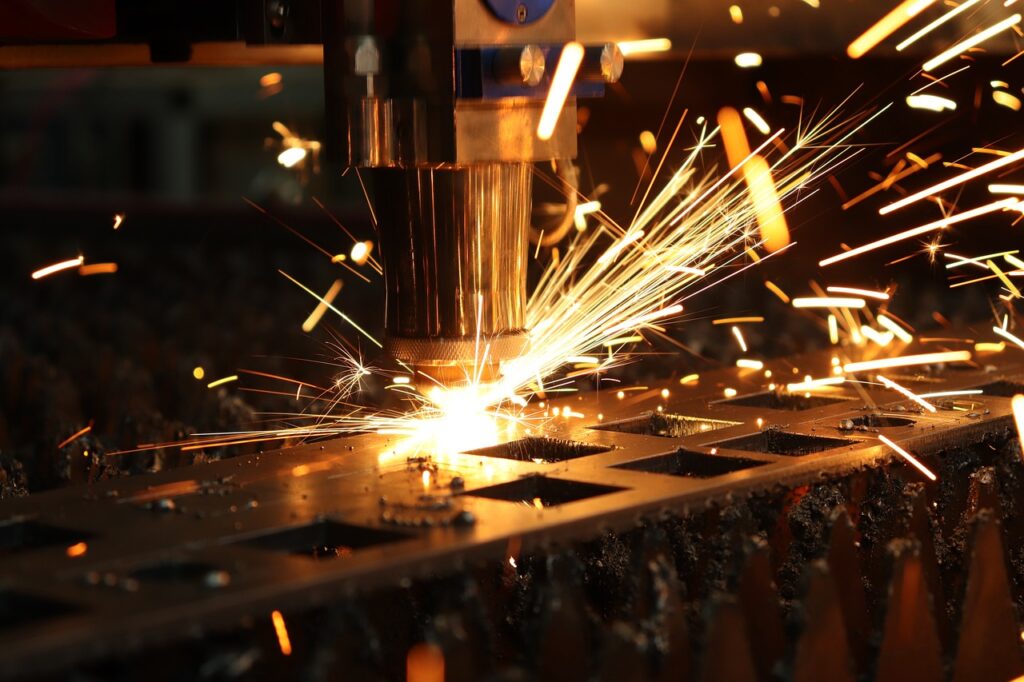

What does a Custom Precision Sheet Metal Fabricator do?

HMLV is a great solution for organizations looking for greater flexibility. It offers an alternative to the processes most manufacturers follow while providing more choices to customers who need special or custom solutions.

High-Mix, Low-Volume Meets Automation: Providing the Flexibility You Need—Without Slowing You Down

HMLV is a great solution for organizations looking for greater flexibility. It offers an alternative to the processes most manufacturers follow while providing more choices to customers who need special or custom solutions.

Working Towards Green Manufacturing

Expanding Wesgar’s sustainability program. While we have implemented various initiatives over the years to minimize the environmental impact of our manufacturing processes,

SUCCESS STORY FOR ANIMAL LOVERS Thera-Clean Microbubbles cleaning system provides the deepest clean for pets by gently removing trapped dirt, bacteria,

Wesgar expands and upgrades its welding department

Wesgar has expanded its welding department by 60% to meet customer needs and upgraded to a custom-built smoke extraction system.

Rugged Overland vehicle kitchens for any environment

SUCCESS STORY FOR ADVENTURERS Compact, rugged kitchen units designed to fit most utility vehicles for home-cooked meals while exploring the great outdoors.

The vital role of sheet metal in the solar industry

Many companies are trying to find better, cheaper, and faster ways to build renewable energy solutions so they can win the global race to provide cleaner energy.

Rising to the occasion by tackling Alpha’s high-stakes production challenges

Wesgar meets stringent demands for Alpha Technology from prototyping to short lead on-time deliveries.

Strategies to mitigate the supply chain crisis

While COVID-19 might not officially be considered a pandemic anymore, there is little doubt that it has left its mark—probably for good. One significant way it has impacted the world is with supply chain issues.

Wesgar scored positive results on a recent client questionnaire

Wesgar was the proud recipient of the Topaz Pinnacle Award at the Manufacturing Safety Alliance of BC (MFSA) gala dinner

How to reduce supply chain costs

One of the highest costs that most companies have is in their supply chain— all the processes and people involved in getting products made and delivered to customers quickly adds up. When managers look at all expenses, their first reaction is to try to reduce costs.

Convert your manufactured parts to sheet metal and save

The constant evolution in manufacturing processes and the increasing demand for cost-effective methods have driven many companies to rethink traditional manufacturing methods.

Fresh Earth Products

ECO FRIENDLY SUCCESS STORY Sustaining the environment with sturdy and efficient home garden composters that keep vermin at bay, produce soil rich

Wesgar was the proud recipient of the Topaz Pinnacle Award at the Manufacturing Safety Alliance of BC (MFSA) gala dinner

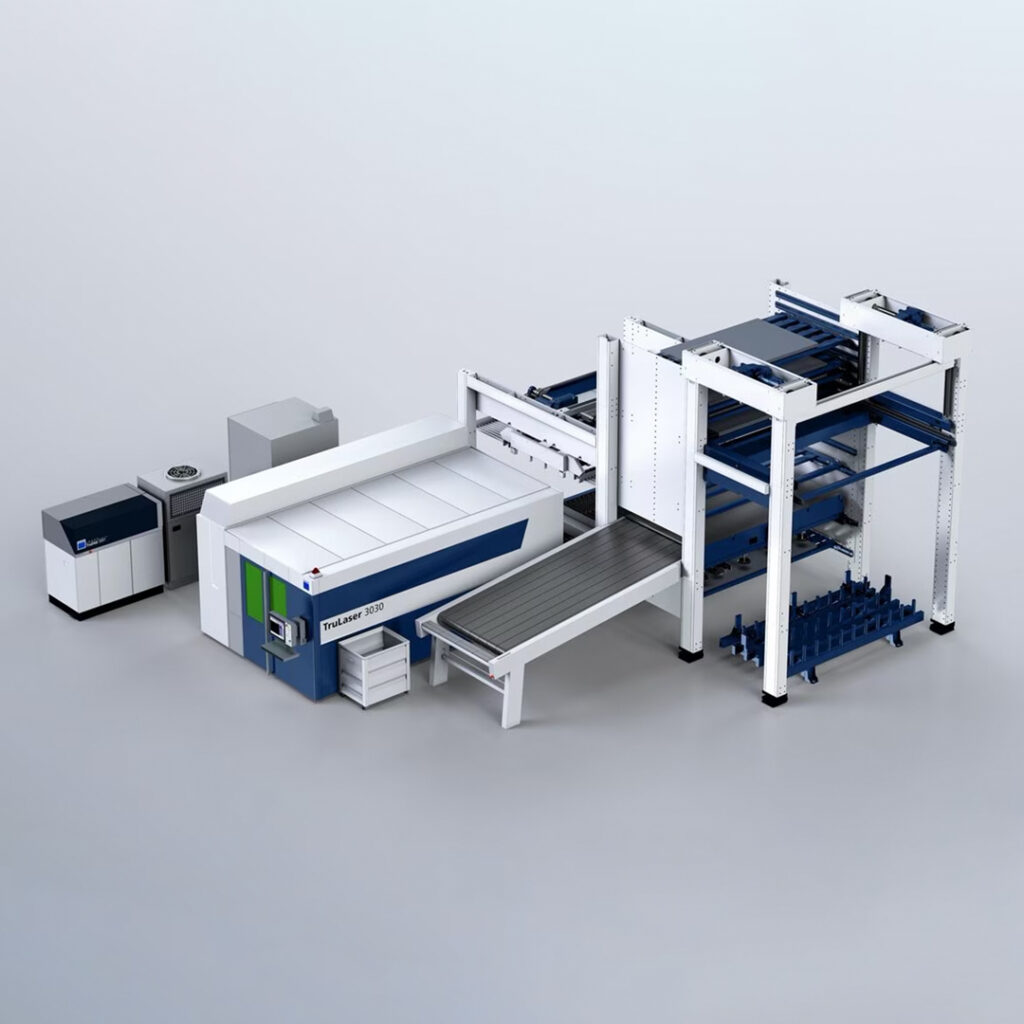

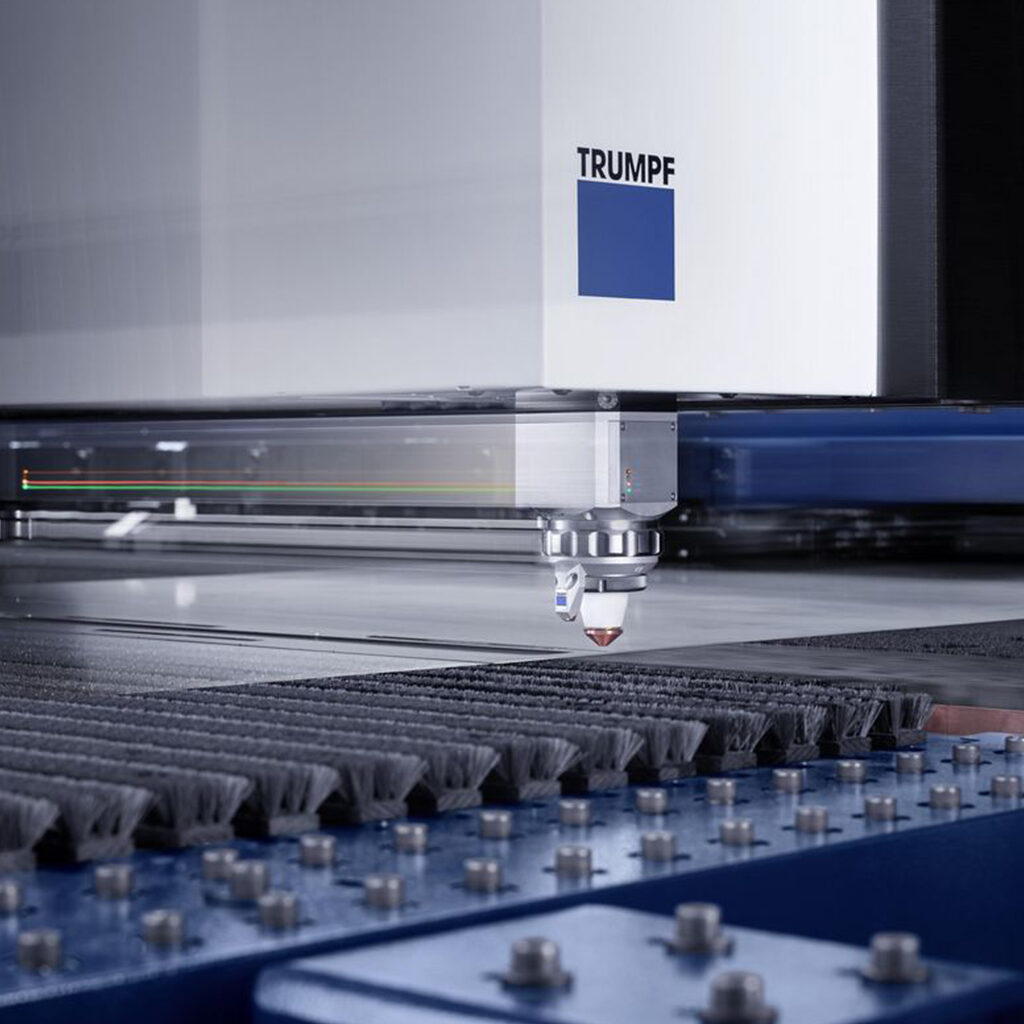

Wesgar’s new automation with LiftMaster system quadruples sheet metal loading speeds

Wesgar has successfully installed the TRUMPF TruLaser 3031 Automation with LiftMaster to manage loading sheet metal more efficiently than ever onto its TRUMPF Fiber Laser.

Powder coatings have become the preferred finish for many industries, used in heavy equipment, marine transportation, electronics, outdoor recreational products, appliances, and more.

Wesgar is proud to announce it has attained a certificate of recognition (COR) for Occupational Health and Safety awarded through the Occupational Safety Standard of Excellence (OSSE) ...

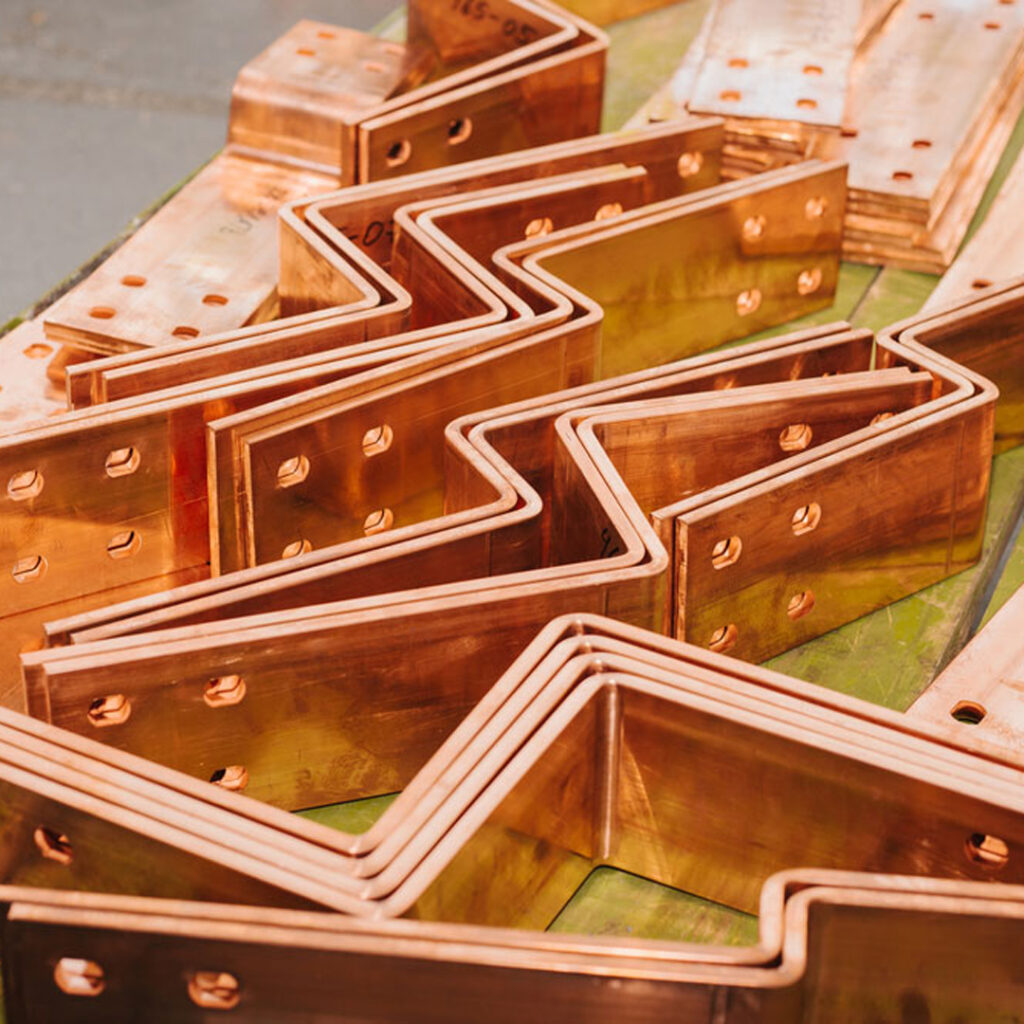

How to select the right bus bar manufacturer for your electrical distribution network

An electrical or grounding bus bar is the backbone of an electrical distribution network, connecting various electrical devices, such as transformers, switchgear, and circuit breakers, and distributing energy to different parts of an entire system.

High-Mix, Low-Volume is not the same as small batches

HMLV is a great solution for organizations looking for greater flexibility. It offers an alternative to the processes most manufacturers follow while providing more choices to customers who need special or custom solutions.

Powder Coating Supply Gun Equipment Significantly Improves Quality

Wesgar’s new powder coating supply gun equipment is now fully operational, producing consistent and high-quality powder-coated parts.

What is Supplier Kanban and why is it important to procurement managers?

If your business is at the mercy of varying customer demands and to keep pace, you find yourself juggling with your parts supplier to keep the supply chain and inventory in check, Supplier Kanban is the perfect solution.

First of Its Kind Italian State-of-the-Art Panel Bender Fully Operational at Wesgar

Wesgar is proud to announce the long-awaited arrival of a state-of-the-art panel bender designed and manufactured by Salvagnini in Italy.

Wesgar’s continued growth, serving clients in Western Canada and the Pacific Northwest, has precipitated yet another expansion of its warehouse facilities in its Port Coquitlam plant.

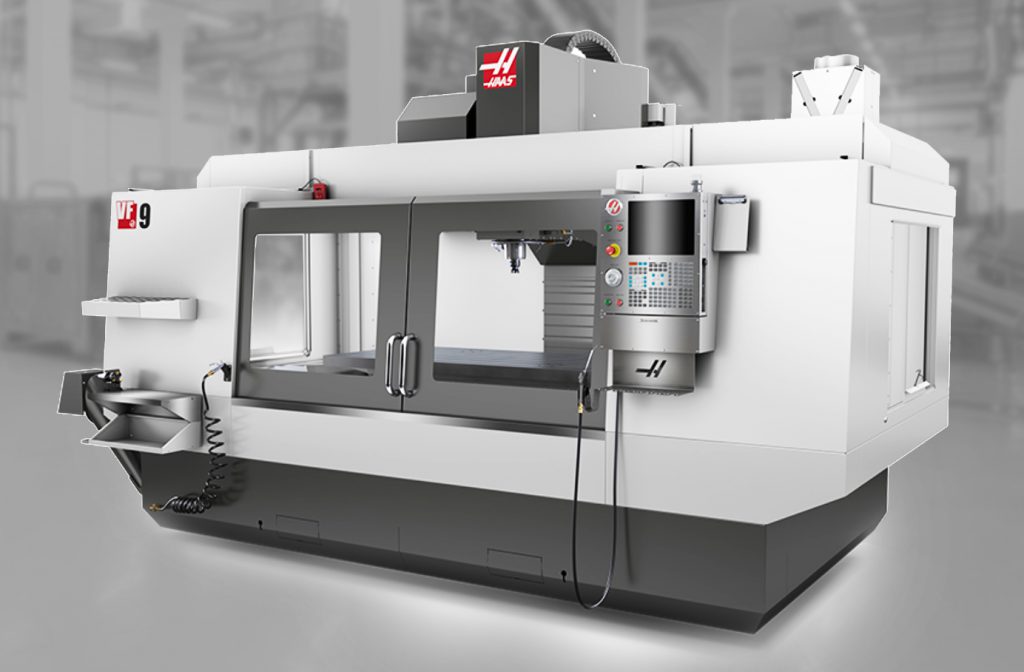

Wesgar Increases Machining Ability and Capacity

Wesgar is pleased to announce the addition of a Haas VF-9 large-frame vertical CNC machining center.

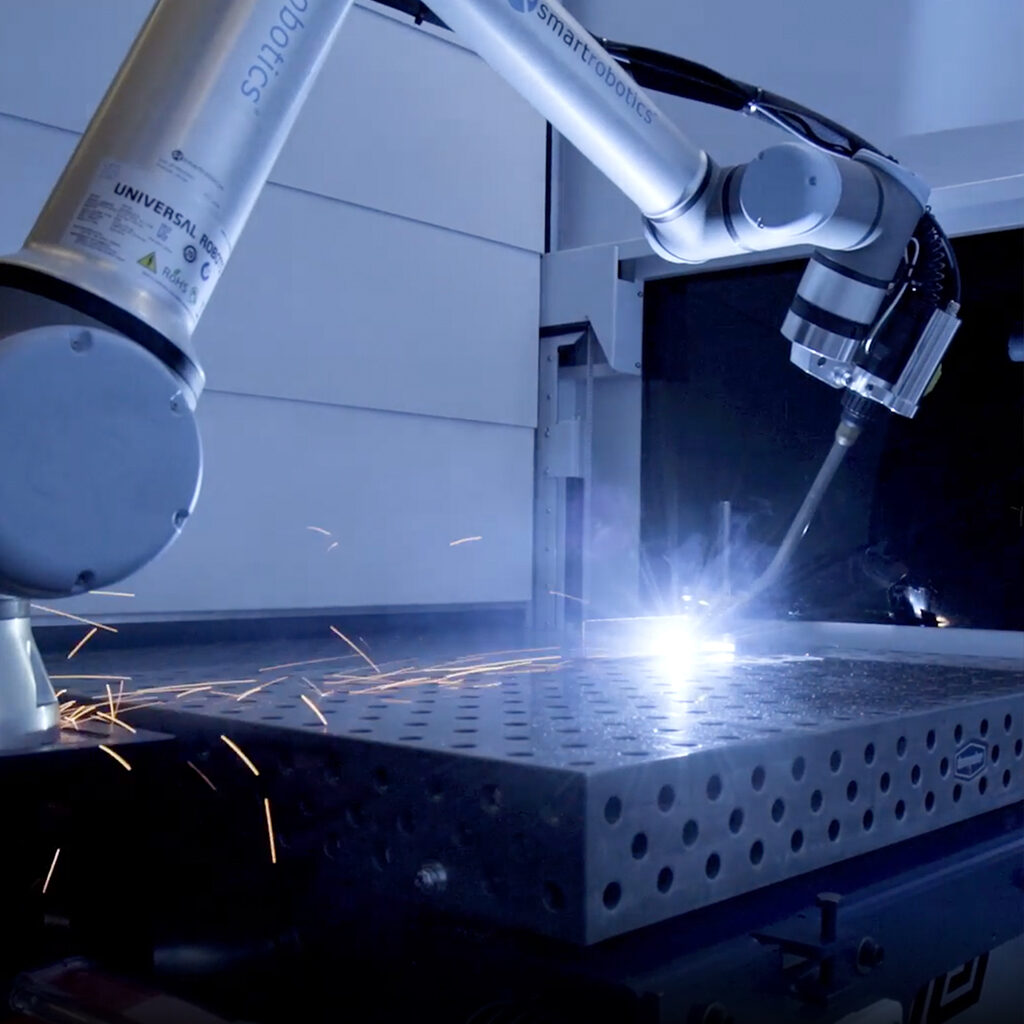

Wesgar Improves Efficiency with Welding Robot Technology

Wesgar’s latest cutting-edge welding collaborative robotic unit, TruArc Weld 1000, is now fully operational in the company’s 100,000 square foot facility in Port Coquitlam, British Columbia

Wesgar Leverages Technology to Meet Customer Demands

Wesgar follows through on its commitment to leverage state-of-the-art equipment in its world-class 100,000 square-foot Port Coquitlam plant with the addition of the new TRUMPF Fiber Laser.

Wesgar Expands Facilities in Port Coquitlam, BC

Wesgar continues to execute on a master plan to expand its operations in order to satisfy the rising demand for its specialized high-mix, low-volume precision sheet metal and copper fabrication.

Major Upgrade to Powder Coating

Wesgar is pleased to announce the completion of a major upgrade to our powder-coat line

Wesgar Installs Haas VF-3 Vertical Machining Center

Wesgar is pleased to announce the addition of the Haas VF-3 Vertical Machining Center to our machine shop

Wesgar Installs Trumpf Trumatic 5000R

Wesgar is pleased to announce the addition of the Trump Trumatic 5000r/1600 Auto Load/Unload.

Wesgar Installs Trumpf TrumaBend V850 and V850S

Wesgar has added the Trumpf TrumaBend V850 to its custom sheet metal fabrication plant press brake equipment.

Wesgar Installs Trumpf TrumaBend V50

Wesgar is pleased to announce the installation of the Trumpf TrumaBend V50 to compliment its press brake equipment.

Wesgar Installs New Wet Paint Booth

Wesgar has completed installing a new J&M wet paint booth.

Wesgar Installs Trumpf TruBend 5085

Wesgar is pleased to announce the addition of the Trumpf TruBend 5058 press brake equipment to its custom fabrication plant.

Wesgar Installs Trumpf TruBend 7036

Wesgar is pleased ot announce the addition of the Trump TruBend 7036 to our press brake equipment.

Wesgar Partners with Weatherhaven

Wesgar has the capacity, experience, and ability to scale up to take care of all your precision sheet metal fabrication needs—from simple compact items to complex and large oversized units.